By Enrique Delgado Avila

The purpose of this secondment was to start having a first contact with ESTECO and to try to think of possible future collaborations with them within the framework of the ARIA project. Also, since SISSA is also located in Trieste, taking advantage of continuing the work previously initiated with them in the framework of ARIA project.

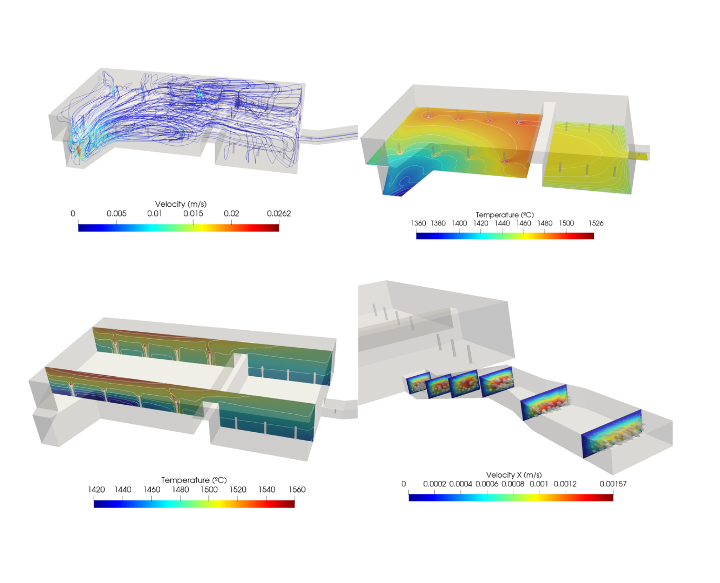

With the ESTECO team, we have presented our work, exchanging our knowledge about ROM applied to industrial problems. They presented me their work about active subspaces, the ROM technique used by them to solve efficiently their problems. With the SISSA team, I continued working on an industrial problem proposed by Bormioli Pharma, for which we have built a non-intrusive POD-ANN model. In this framework, we have developed a mathematical model for molten glass fluid flow in a furnace melting basin. In a first stage, we have discussed which physics are the most relevant for the application at hand, and therefore must be incorporated by means of appropriate partial differential equations in the model; the remaining physical contributions will be included instead by means of forcing terms or boundary conditions, or simply deferred to a postprocessing stage. The molten glass is assumed to be a viscous

fluid, which is heated in two ways: by methane combustion and by electric booster heating. The two heat sources will be modelled differently: on the one hand, the heat flux resulting from the methane combustion flame is incorporated into the energy of the system by means of a boundary condition. On the other hand, a partial differential equation will be set up to model the booster heating, by considering an electrical potential equation. Thus, we are dealing with a (non-linear) multiphysics system, where the velocity, pressure, and temperature of the fluid are coupled with the electric potential produced by

the boosters.

We have considered five parameters that mimic a change in operating conditions in the furnace: One parameter corresponds to the amount of energy coming into the system by methane combustion, and the other four correspond to the voltage of the boosters. Thus, we parameterize the energy that is incorporated into the system. To achieve a real-time visualization of the furnace state, we rely on a non-intrusive ROM based upon Artificial Neural Networks (ANNs) for the molten glass fluid flow model. During the training phase, we construct the reduced spaces by a Proper Orthogonal Decomposition (POD). During the evaluation phase, we seek a reduced-order solution of the problem as a linear combination of the POD modes, where an ANN is queried to produce the weights to be employed in the combination. An animation of the solution variations resulting from the modification of the value of different process parameters can be viewed on the website https://youtu.be/yRNQaGVmXF4.